Process Engineering Consultancy Services in India, Service Provider in Pune, Saudi Arabia, Egypt, Malaysia

As a leading Process Engineering consultancy service provider, Vincitore Edutechnologies' team provides technical expertise and compliance help across a wide range of sectors in cities like Pune, Mumbai, Aurangabad, Goa, Nagpur, Bangalore, Chennai, Hyderabad, Kerala, Coimbatore, Nashik, Indore, Ranchi, Kolkata, Belgaum/Belagavi, Ahmedabad, Vizag, and Kochi. Our engineers assist clients in developing a methodical approach to new innovations or plant upgrade initiatives.

Also, we provide Process Engineering Consultancy Services in India, Saudi Arabia, Egypt, Malaysia.

Our team includes Chartered Chemical and Mechanical Engineers with the necessary expertise and experience to provide guidance in a variety of sectors. Because of our technical competence, our clients are able to discover plant concerns early on and develop solutions to make essential changes.

How can we assist?

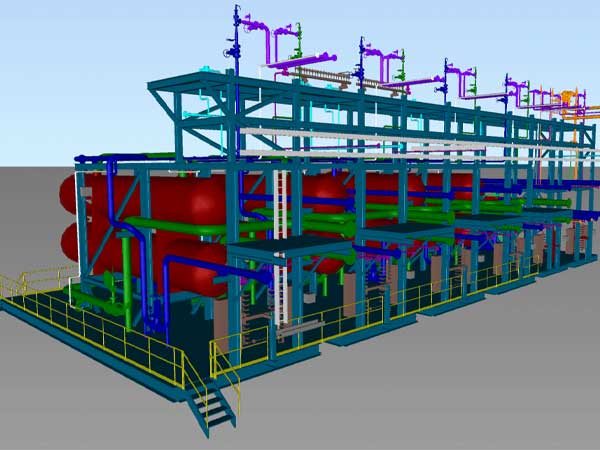

Vincitore Edutechnologies, a leading Process Engineering consultancy services provider, assists customers in meeting their regulatory requirements for industrial wastewater in a cost-effective manner. This can include tasks such as designing and implementing waste minimisation processes on production lines, operating and maintaining existing treatment plants, including troubleshooting and process optimisation, selecting, specifying, and commissioning new treatment plants, liaising with regulators, and providing expert witness services.

In addition, the team contributes technical experience to the completion of Technical Due Diligence on the creation of new processing plants or acquisitions. This work frequently leads to contract support, working as Owner's Engineer, and doing Performance Testing on new plants and equipment.

Because of their methodical approach, the team can carry out this work across industries, but they have special experience with food and drink, recycling, energy from waste, and anaerobic digestion facilities.

Following are the various sectors that we provide our services in:

Vincitore Edutechnologies have a department staffed primarily by engineers who develop new products, a task that typically involves extensive research. After the research, model is also design and also manufactures the plant from it. We had also developed model from R & D level to Commercial part in case of Herbal Extraction, Cardanol Distillation Plant, Essential Oil Extraction, Terpineol Distillation Plant, Used Oil Recycling Plant, Ethanol Manufacturing Plant, Biodiesel Manufacturing Plant, Edible oil Plant.